Aside section

Cases

"Stalkanat" implemented full-scale digitalization of production sites in the Industry 4.0 concept on the IT-Enterprise platform

The project to build a modern, comprehensive production management system based on the IT-Enterprise platform suggested a logical chain of sub-projects: MDM, WireDesigner, MPS, MRP, APS, SmartQuality.

Progress Service implemented end-to-end business processes "from order receipt to shipment of finished products" at IT-Enterprise

Progress Service (Lviv) is one of the leading companies in making high-quality and affordable shoes. Together with IT-Enterprise, it is developing and improving a large-scale project to digitalize its business processes.

Elsewedy Electric has implemented IIoT Monitoring and end-to-end integration of production management levels on the IT-Enterprise platform

The partnership with Elsewedy Technology has resulted in a state-of-the-art Lite MES application providing synchronization of digital tools for order processing, production planning and job order performance.

"Stalkanat-Silur" increased production capacity by 20-50% thanks to the organization of the Smart Factory cycle from IT-Enterprise

Трансформація виробництва компанії «Стальканат-Сілур» за принципами Industry 4.0 сприяла оптимізації кожного етапу виготовлення продукції.

"Stalkanat-Silur" reduced time-to-market by 20+% thanks to the transformation of the technological chain in production together with IT-Enterprise

Time-to-market is reduced by 20+% meaning it takes less time for the product to pass through the process chain stages. ~1 Million UAH is saved each year, which is ~3% of the total volume of transport services.

JSC "FED" implemented operational production planning and optimized order fulfillment times with IT-Enterprise

Timely execution of customer orders due to efficient planning of production capacities operational load.

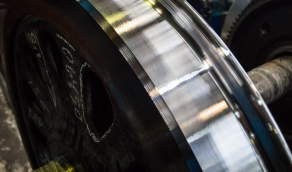

INTERPIPE implemented a digital production transformation project together with IT-Enterprise

Interpipe is an integrated pipe and wheel company, a member of the TOP 10 list of the world’s largest seamless pipes’ producers.

"Rivne High-Voltage Equipment Plant" reduced the TVC by 40-60% for all types of products thanks to IT-Enterprise

Rivne plant of high-voltage equipment reduced the manufacturing lead time of orders by 40-60% with the IT-Enterprise ERP system implementation

Improving the predictability and manageability of the enterprise due to the cost accounting in production Lviv Locomotive Repair Plant

Reduction by 15-20% of critical repairs cycles to the Lviv locomotive repair plant (LLRZ) due to the implementation of operational accounting of production costs on the basis of IT-Enterprise

"Zorya"–"Mashproekt" increased production output by 30% thanks to operational production control on the IT-Enterprise platform

How a science-and-production complex of gas turbines "Zorya" - "Mashproekt", one of the world's leaders, has achieved an increase of 30% of production output through operational control of production